Feature:

High frequency vibration pressing inserts the wire by batches, which can save 5-10% wire cost comparing to the traditional pushing insertion.

External individual wedge insertion ensures products change-over be completed within 30 minutes. It also largely reduces the production suspending because of broken wedge blades.

Parameter:

Slots No.:8-48

Stator ID: 30-80mm

Core length: 10-130mm

Min wire diameter: copper 0.09mm; aluminum 0.13mm

Capacity per hour of winding insertion part:8 -16 slots: 250-300 pieces; 24 slots: 150-200 pieces

Capacity per hour of wedge insertion part: 8-16 slots: 400-600 pieces; 24 slots: 250-400 pieces; 36 slots and above: 200-300 pieces

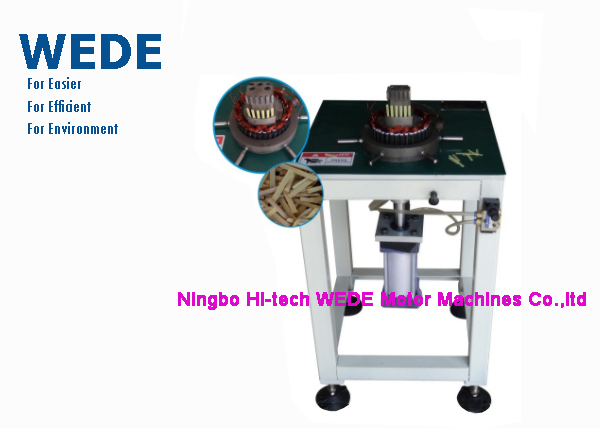

Main composition:

Winding insertion part:

PLC: MITSUBISHI

Servo motor: PANASONIC

Wedge insertion part:

PLC: DELTA

Cam is used for driving.